Chemistry Analysis

- Acetone, Alcohol, Nitric acid and Sulfuric acid are used be the chemical raw materials for analysis.

- We scrub the surface of component by Acetone in a certain direction with fixed number of times,to ensure that whether the component was reprocessed or reworked.

- The chemical materials of IC products need dissect through immersion, the first get rid of the surface of the epoxy resin products, second remove the gold and wafer. so the original loge of wafer, defects, good or not will be showed by HD microscope that know the reason for the failure products. Expecially the chemical anatomy soaking technicians of us have long experiences with 10years in every immersion dissection process to maintain a high lever.

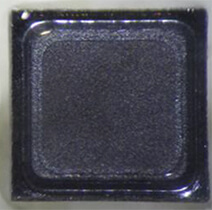

X-RAY And ROHS Test

- X-RAY device can confirm whether it is good for wafer, wire bond and die bond.ROHS test can confirm whether it is environmental protection by the product pin and the solder coating of photovoltaic equipment.

- The device is EOX brand series, which can accuratly determine the lead content of the product pin, as well as can confirm the lead for the non-ferrous metal pin and the surface of the pin incluiding CrCdPbHg, CrCdPbHg, CrCl.

- The picture above took by X-RAY is the product pin bitmap.as the the small red arrows show,wire bones and wafers are open circuit and short circuit.it caused that the product can work, it is a big risk to the entire circuit. When checking the internal structure via the X-RAY that can be magnified 1,000 times, we’ll filter this kind of product out.After that, we do the proper functional testing for other product which are in good condition. Finaly, we get the good quality parts for customers.

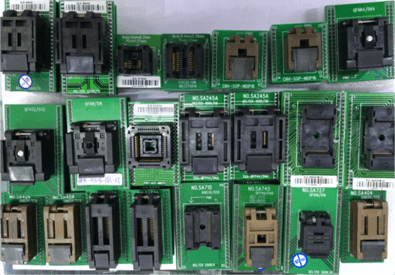

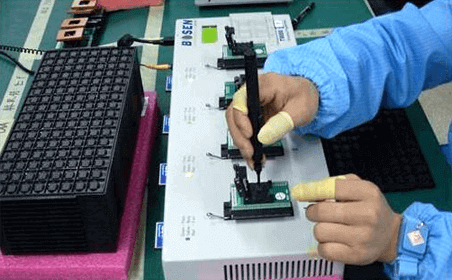

Programming Function Testing

- There is hundreds of different pacakge testing sockets and adaptor to check various of devices including market famous programming tester, eg: XELTEK 7500 6100 3000U, SMARTPRO 5000U

- XELTEK 7500 6100 3000U 5000U programming tester is specificity program, which to test ID read, write, verify program as well as blank checking for digital memory Mictrocontrollers, MCU and so on.

- To ensure the correct read and write of the chip internal storage, we do storage capacity test for digital memory and flash memory.

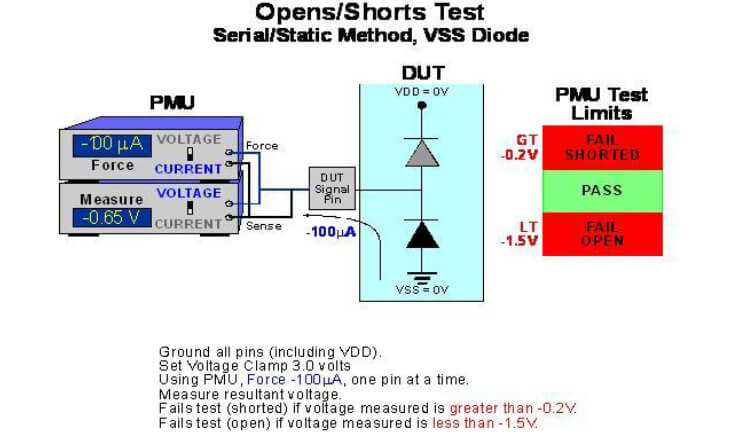

Open/Short Test

- To test the lower diode,which is connected to VSS,use the PMU to force a negative current of approximately-100μA.Set the lower test limit of the PMU to fail if the measured result is less than-1.5V to detect an open . Set the upper PMU limit to fail if the measured result is greater than -0.2V to detect a short. This test method is used to test signal pins (inputs an outputs) but not power pins such as VDD or VSS.

- Power and ground pins may also be tested for an open condition, but their structure is different from that of a signal pin. Test the power pins, observe the measured value on a good device, and set the test limits accordingly.

- To test the upper diode, which is connected to VDD, use the PMU to force a positive current of approximately+100μA. Set the upper test limit of the PMU to fail if the measured result is greater than 1.5V to detected an open . Set the lower PMU limit to fail if the measured result is less than 0.2V to detect a short. This test method is used to test signal pins (inputs and outputs) but not power pins such as VDD or VSS.

Final Function Testing

- Compare IC product delay output function signal and high low level voltage.

- Measure the product DC characteristic curve and repetitive peak reverse voltage in MOSFET\Diode\TRANSISTOR\IGBT\ TRIAC.

- Measure product Output load Regulation in LDO IC product.

HD Visual Inspection

- HD Visaul inspection equipment is 16 million pixels and 1/2.33 inch image imported Panasonic CMOS image sensor, which the view is wider than 1/3 inches. Also to output HDMI with 1080P 60 frame image (camera resolution 4608*3456).

- Confirmed the solder ball is good in BGA package including oxidized, reball, flat and consistent.

- Confirmed the surface of the product is the same as specification marking